Manufacturing

Methods and Process

Our facilities host high-capacity machining cells, which give us a large bandwidth for production volume. Our machining service utilizes advanced techniques and precise equipment to shape and cut materials with exceptional accuracy, providing high-quality components tailored to your specifications and requirements.

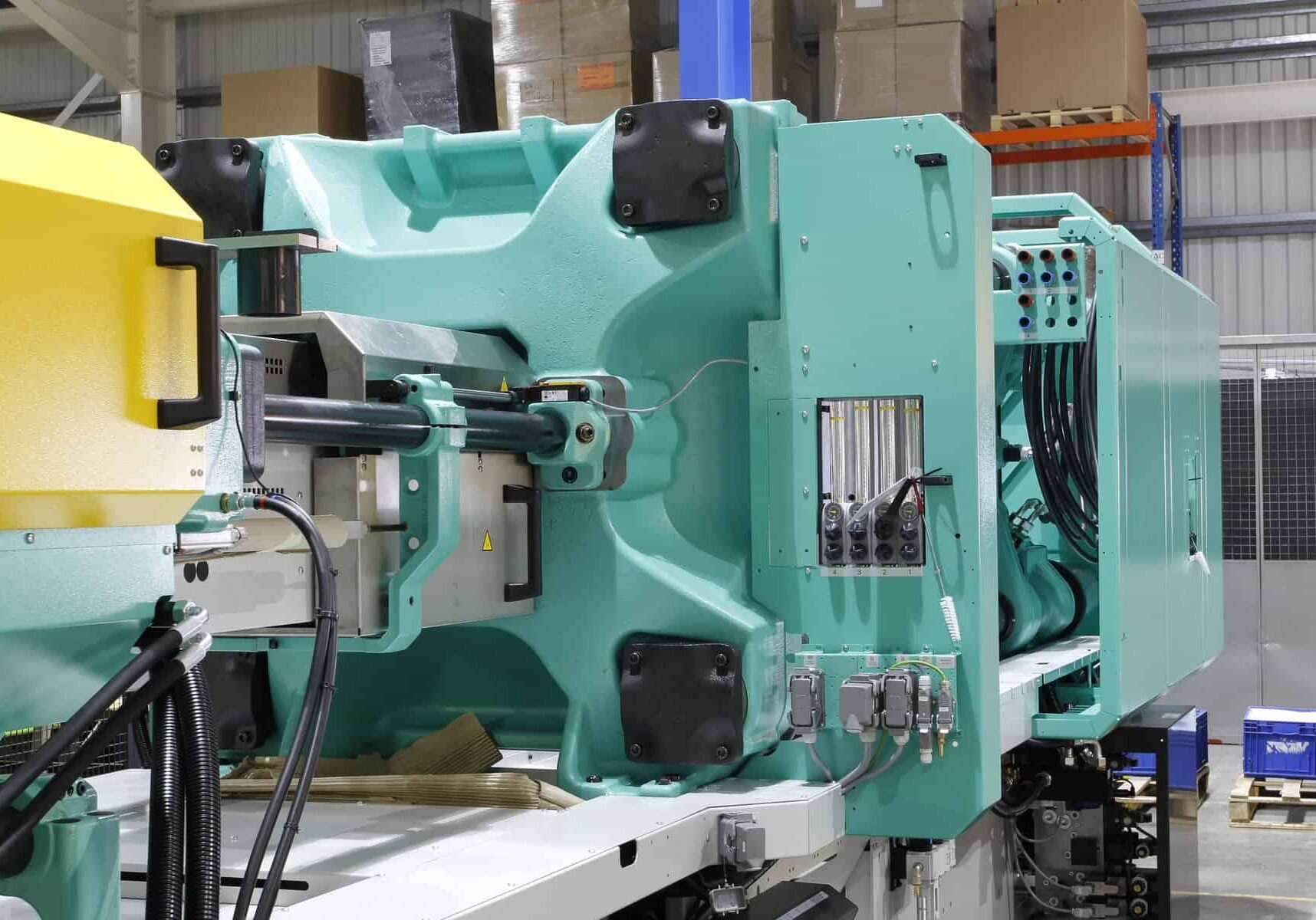

We specialize in producing plastic components and creating complex shapes through injection molding, blow molding, and vacuum casting, ensuring consistent quality and precise replication. Our molding department makes low-volume production runs through lights out 24/7 product manufacturing of millions of parts.

We offer various casting methods, including die casting, sand casting, and investment casting, enabling the production of intricate metal components with exceptional detail, strength, and durability. Our casting capacity is good for production runs over 500 pieces, gaining the most benefit with large volume runs.

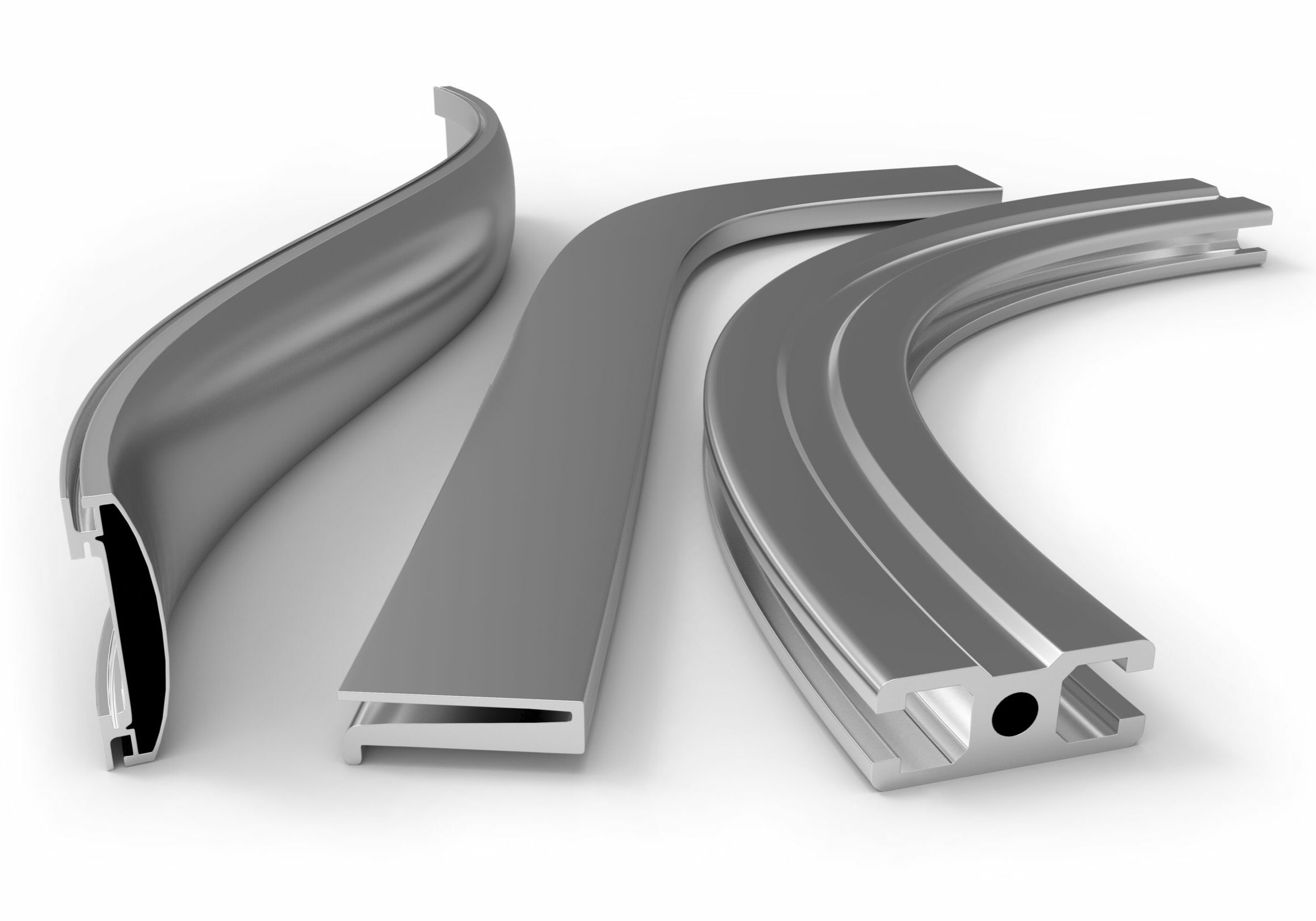

Forging, stamping, bending, and wire forming, allowing us to shape metals into desired forms and structures with precision and efficiency, meeting your design and quantity needs in an accelerated timeframe.

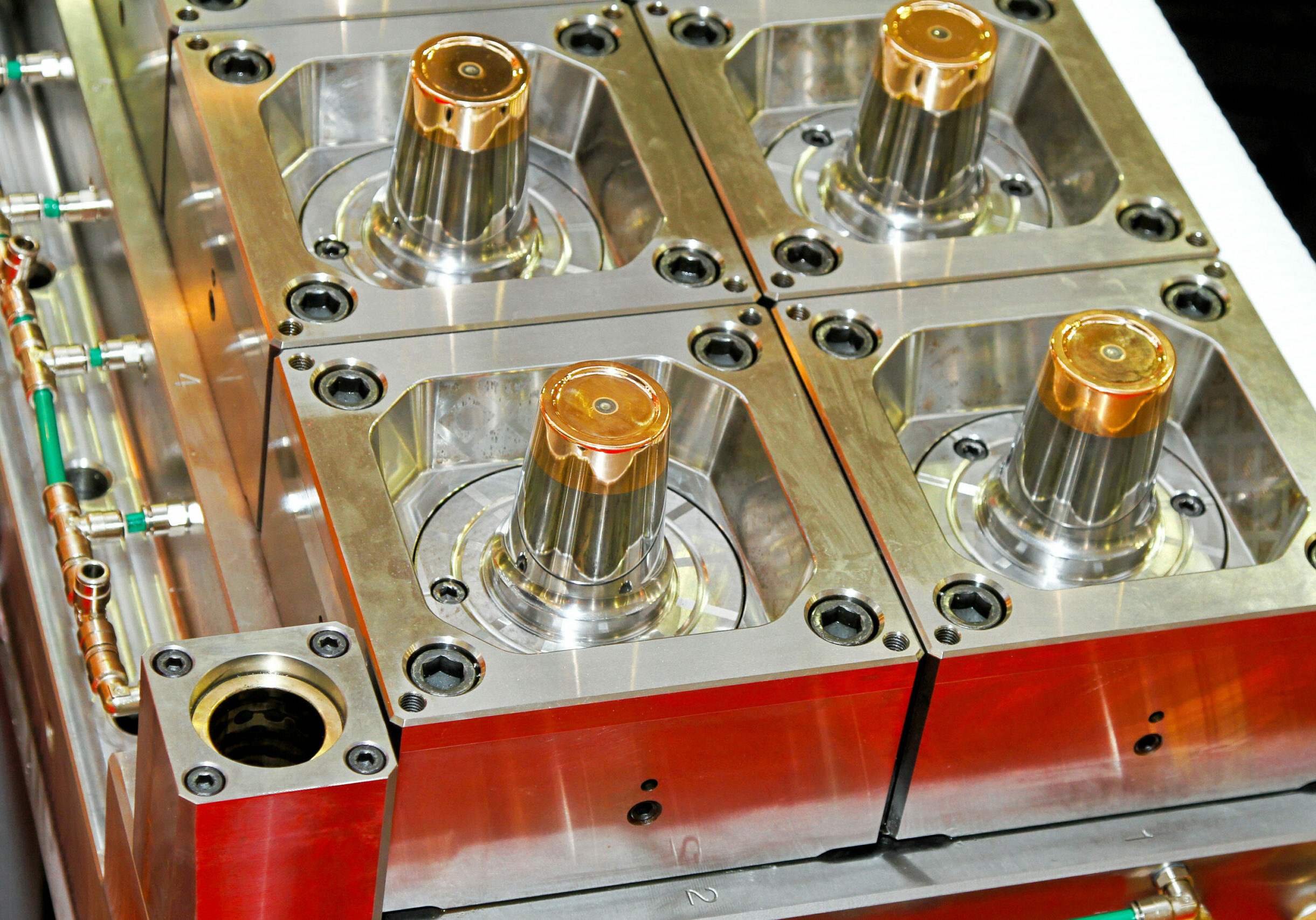

We provide custom tooling and molds for your molded or cast parts. Which can be used in our facility or can be shipped to the factory of your choice. Our tools and molds ensure efficient and accurate manufacturing.

Finishing adds the final touches to your products, offering surface treatments, coatings, and precision polishing to enhance their appearance, durability, and overall quality, providing a refined and professional appearance.